CREATING THE PERFECT CONSTRUCTION JOINT

© Copyright Shutter Strip

Date of issue: 23 October 2022

Version 1.3

SHUTTERSTRIP CONSTRUCTION JOINT FILM is a water-soluble film that contains organic concrete retarders; the film is non-hazardous and sealed in protective liners.

Ingredients determined not to be hazardous

Appearance: Yellowish Film.

SHUTTERSTRIP CONSTRUCTION JOINT FILM can be easily attached to any area of a formwork/shutter to deactivate/slow the setting of wet concrete laitance to expose aggregates to create a keyed construction joint or for exposing starter bars and for aesthetic decorative purposes.

Before application, it is recommended to wipe clean and dry the desired area of the formwork/shutter to achieve the best adhesive bond of Construction joint film to the Formwork/shutter. ShutterStrip can be applied to wood, metal, polystyrene and plastic moulds.

A) If formwork is wood, use pins, tacks or a stapler and secure the retarder film to the formwork shutter

B) If formwork is not wood then use sticky tape and stick across edges. (Remembering to lift the corners of the protective liner before securing or applying tape)

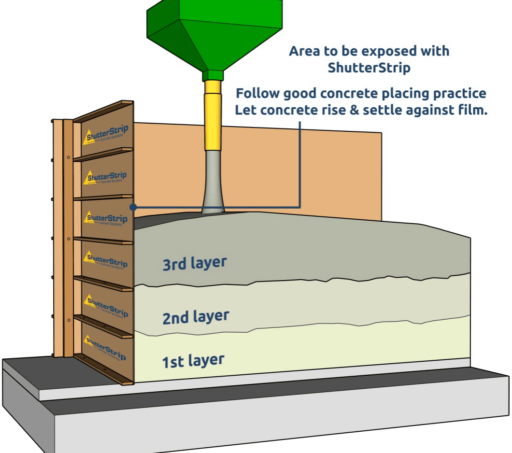

Good concrete placing practices must be taken. Treat the area that is to be exposed the same as if it was a finished product. Make sure the layers are well vibrated together and that the face is well vibrated or the outside shutter is tapped/hammered all over.

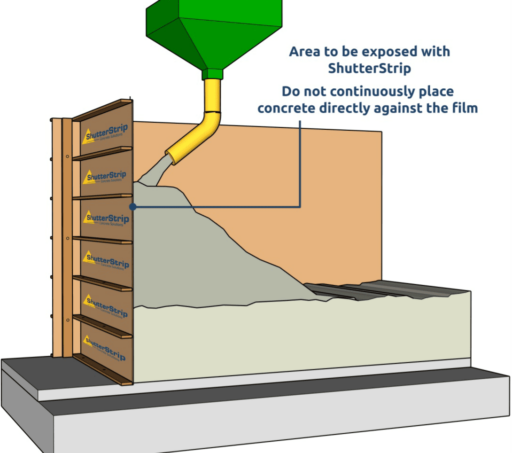

Do not continuously pump/place concrete directly against the area of the formwork shutter that the retarder film has been applied to. If there is no other option to this, place a strong plastic sheet over the retarder film and when the shutter is being loaded, pull the plastic sheet up accordingly, allowing the concrete to come into contact with the film. If these procedures are not followed, this could result in the film being rubbed away, leaving areas of unexposed aggregates.

When the underlying concrete has hardened and the formwork/shutter has been removed, the de-activated area will be visible, scrape the visibly affected area and then wire brush or jet wash with water to expose the aggregate depth of 3mm to 5mm.

Depending upon the temperature and as determined by the approved mock-up panel, it is recommended to expose the aggregate as soon as the formwork has been stripped. If the laitance has started to harden, simply jet wash with water and continue with a wire brush!

LAITANCE CAN BE REMOVED UPTO SEVEN DAYS AFTER CONCRETE PLACEMENT IF KEPT IN SHUTTER.

Suitable PPE, including protective gloves, safety glasses/goggles/dust mask and protective clothing should be worn if wire brushing or jet-washing.

If any of the films are left on the formwork shutters, wash them down with water, and if needed, remove the adhesive layer by peeling it from the formwork.

Proceed with the application after approval of the test area. Results may differ based on statistical variations depending upon concrete mix, temperature and humidity and actual site conditions and curing conditions.

The following guidelines should be noted

Dispose of by site rules and local regulations. All used packaging should be taken to an approved waste handler for recycling.

Shelf life in original, unopened packaging is 2 years from the date of purchase.

Join our mailing list to download the Shutterstrip brochure to see how we innovate to reduce costs, protect the environment and make working practices safer.

Your information will be processed in accordance with our privacy policy

Shutterstrip takes health and safety extremely seriously. Our Material Safety Data sheet is here

Download